At Pariani we always consider with care the processes involved in the manufacture of our products, because a good product is one that not only meets the customer’s expectations but also ensures the right profit margin.

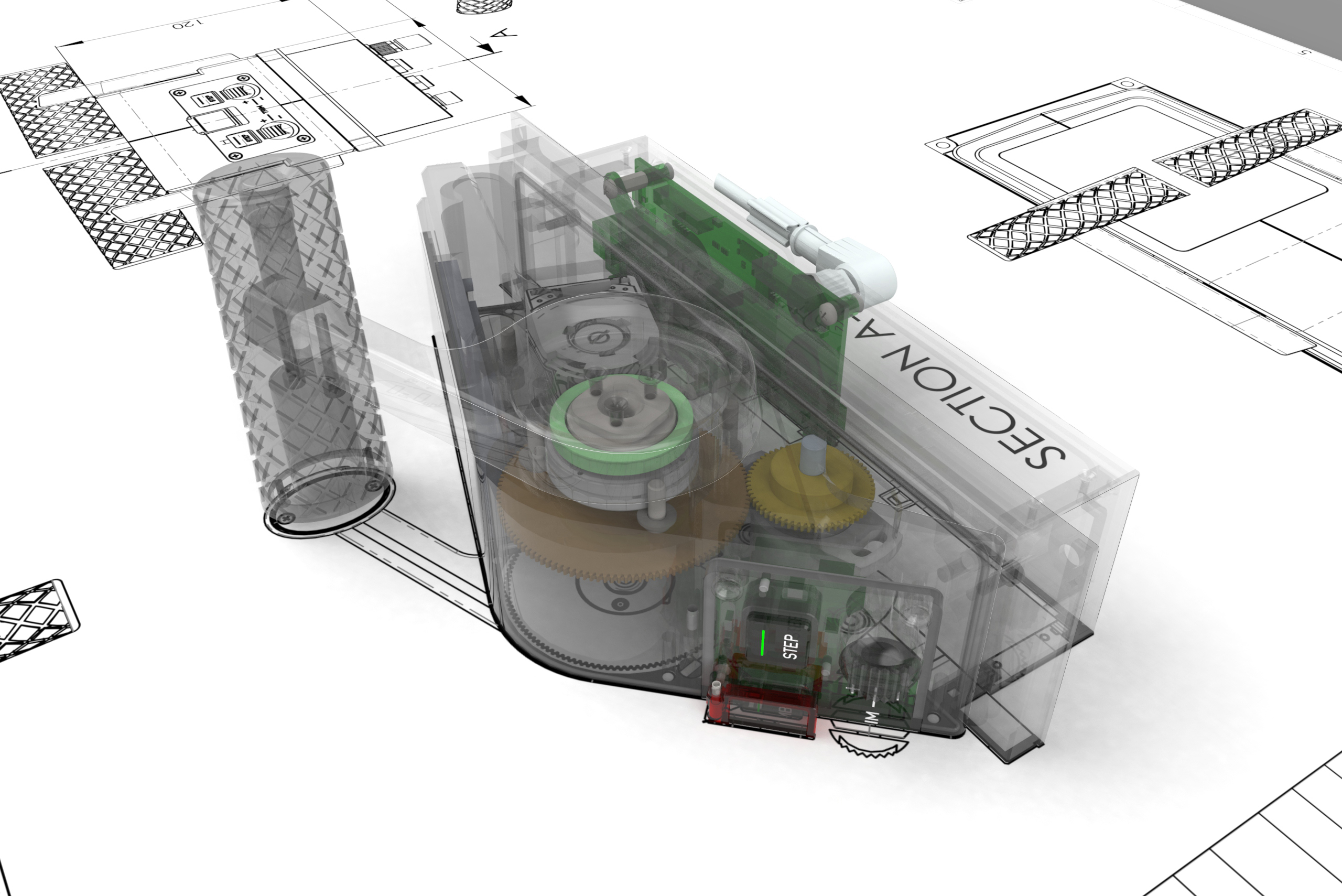

We call it “integrated design” because we make sure there are no barriers between design and production and also because know-how is put to use in both departments and is seen as one of the company’s assets.

The designers can learn from the new solutions perfected by the production department, and apply them to create and design even better parts and assemblies.

In the meantime, the production department faces the new challenges raised by the engineering to to move the limit further and further, because at Pariani we take care over the design and manufacture of our products, rather than simply make them.

The key problem every time we install a new production facility is to make the engineers fully understand their potential and opportunities, all this while designing and manufacturing continue without interruption.

The result is greater efficiency of the processes and planning with an eye for better managing bottlenecks.

We have revolutionised many manufacturing processes over the past five years.

For example, we installed new 5-axis milling centres with large work areas and high-productivity multitasking centres in the CNC department, so that we reduced the outsourcing of machining to zero, improved process control and created new workplaces.

This new organisation of the mechanical department has allowed us to optimise workflows and ensure faster delivery.

Stay tuned to discover other interesting stories about our company.