WAC Solo, here’s how the future borns

https://www.pariani.com/wp-content/uploads/2019/01/Business_WAC_solo_green_550.jpg 550 380 Pariani Srl Pariani Srl https://www.pariani.com/wp-content/uploads/2019/01/Business_WAC_solo_green_550.jpg

Automatic processing, hand finishing, strong tests and exclusive materials: let’s see how the most innovative and ever desired integrated control bridge borns.

System design

The process begins in our engineering department where the system engineer defines with the shipyard the list of equipment to be managed by the new bridge.

For each of these systems is defined the command tree that will be implemented and/or the related options.

Design language

The next step is the definition of the design language and the materials.

Our designers work closely with the customer to select the right combination according to their tastes.

Each yacht is an unique piece and so must be your console. Every detail can be customized according to your needs.

Mechanical and electrical design

The work of engineers begins only after this phase, they industrialize every form and design the electronics that will give form and function to the new console.

Our design phase covers all aspects of the product development process, such as design, verification, sustainable design, communication and data management, through an integrated and continuous workflow.

Production

CNC Machining

To achieve the best possible precision, the parts are built with automatic processes, such as CNC machining for mechanical parts and pick & place assembly for electronic parts.

The mechanical department can count on 3-4 and 5-axis CNC machining centers, even on large dimensions, in order to work any piece and any material that has been defined.

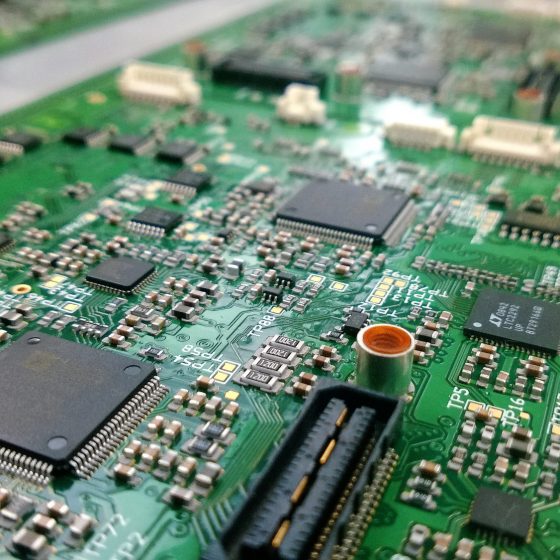

PCB Assembly

Our electronic boards are assembled on very precise pick & place machines able to mount micro-components with minimum dimensions up to 0.250×0.125mm.

After the assembly, the boards undergo a vapor phase welding process which allows a superior, fault-free and completely uniform welding quality with a 0% risk of overheating.

Glass Milling

With advanced CNC-machines, we can mill all kinds of shapes and notches in a glass bedding which machines edges to a very high quality polished finish

Craftman work

But you know, art is not a process of the machines and so all the aesthetic finishes are carried out in a traditional way by expert personnel.

Surface treatments, painting, seawing, everything must be in the name of the single piece, not made in series but not imperfect and therefore, this phase takes 2 months. Everything must be perfect, without compromise.

Stress screening and Test

Every mechanical part is dimensional checked with a very strict dimensional control.

The electronic boards are 100% tested and subjected to an operating environmental stress screening (ESS) that subjects them to 72 hours of thermal cycles cooling them down to -20 ° C and then heating them up to 60 ° C many and many times.

In this way, any functional imperfections in the assembly processes are amplified and intercepted.

Cards that do not pass this very severe tests are rejected and dismissed.

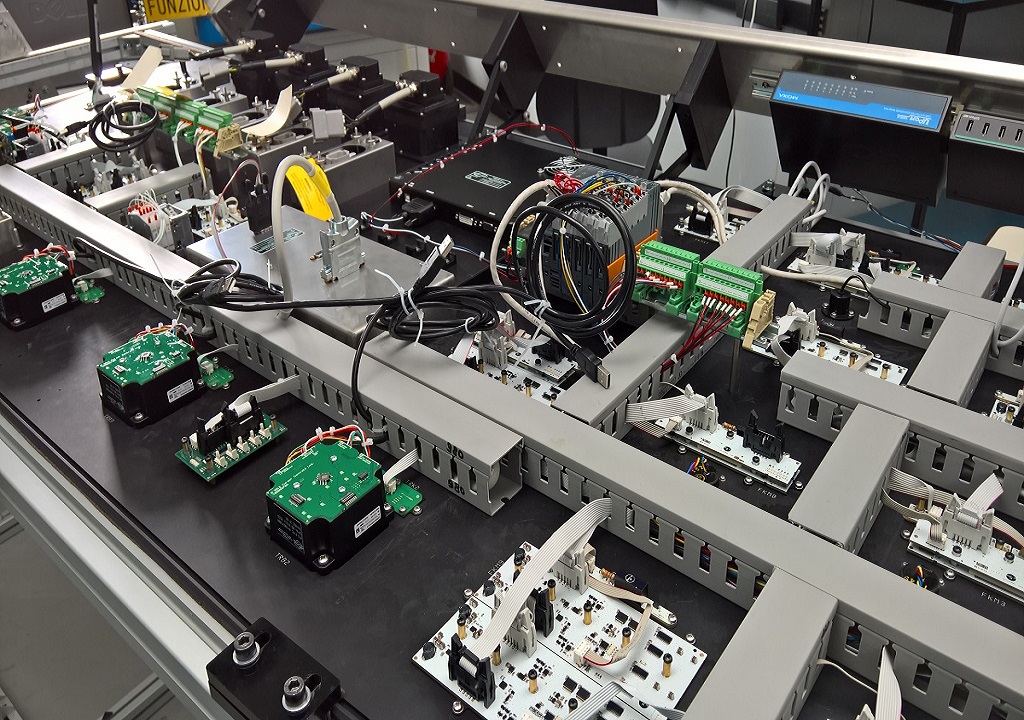

Final Assembly

Moving to the Assembly Area, the final assembly team of mechanics and electricians alternate their effort for about two weeks.

The parts are assembled according to standardized procedures at the end of which tests are provided to guarantee precision and repeatability at the highest levels.

An artisan product that is assembled with aeronautical methodology acquires a high value, destined to last over time.

End Line

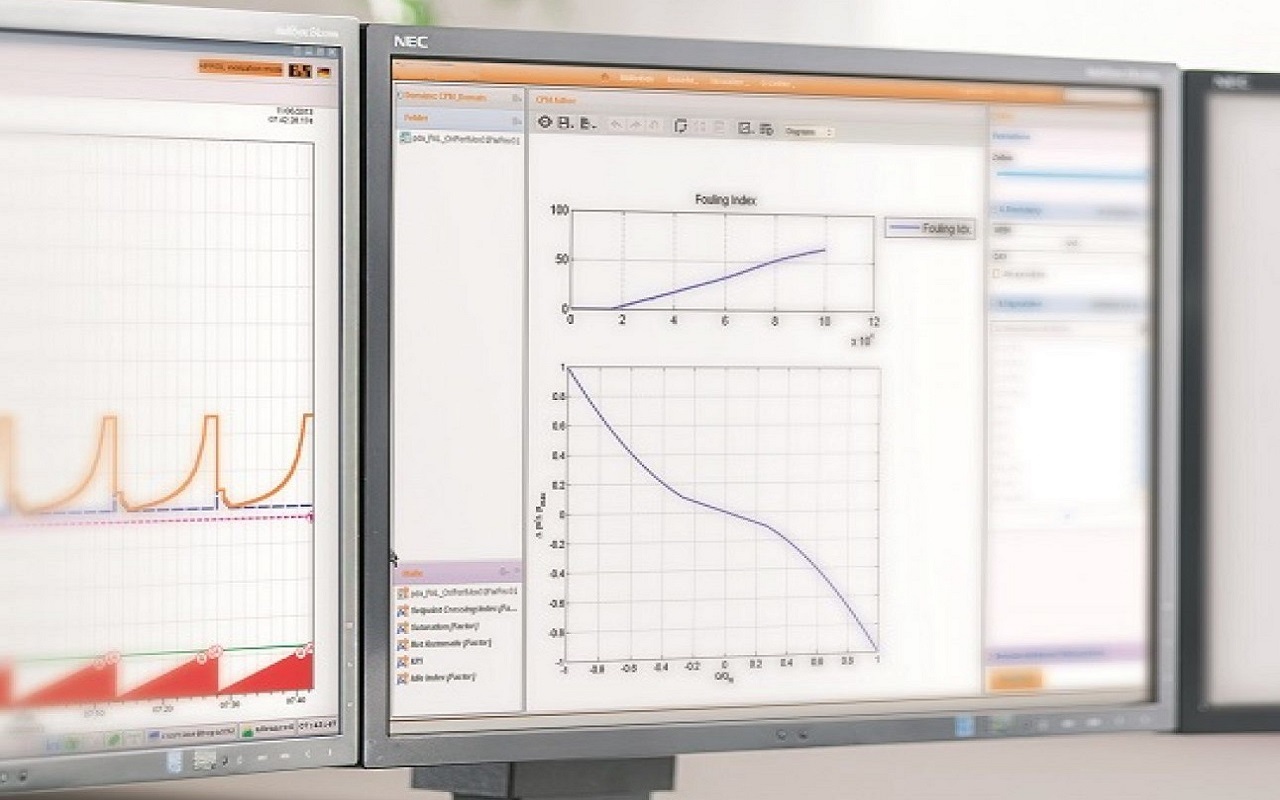

Once assembly is complete, an endurance test is performed at the end-line.

The console is powered and stimulated with automatic tests for at least 7 days.

In this phase, every parameter such as board temperature, bus data errors, component status and many others are monitored by the “built-in-test” process.

Each anomaly is recorded and managed according to strict internal rules.

FAT

When this pure technology artwork is ready, a complete FAT is performed in the presence of the shipyard and of the naval register which, after having analyzed all the project and system documentation, certifies its suitability for naval use, the famous “Type Approved”.

Delivery

The console is now ready to be shipped to the shipyard.

It is now dismantled into sub-assemblies and packaged in a suitable container to ensure its transport, protected from impacts and adverse atmospheric agents.