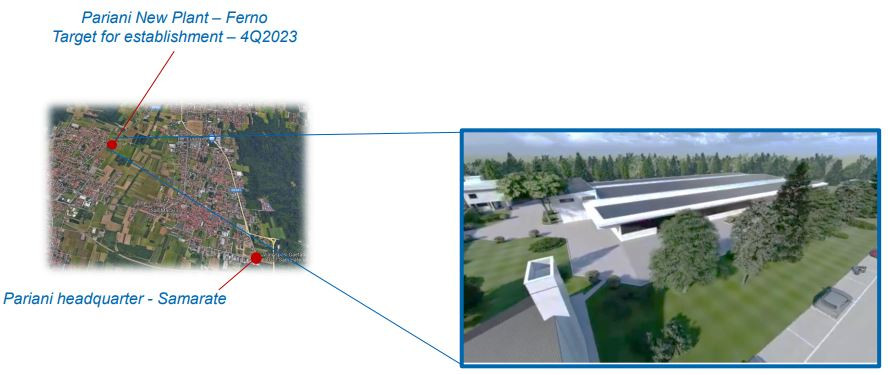

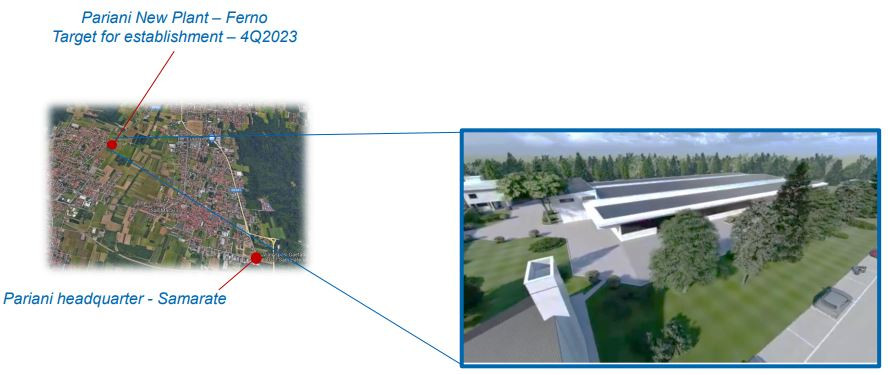

Pariani srl guarda al futuro degli equipaggiamenti aeronautici riqualificando un importante area nel comune di Ferno per ampliare la propria sede operativa.

E’ oggi in corso la riqualificazione del nuovo stabilimento direzionale e produttivo che coprirà, inizialmente, un’area di 5000m2 e sarà situato a meno di 2Km dalla sede di Leonardo Helicopters, uno dei principali clienti.

Pariani srl è una PMI Italiana caratterizzata da una forte capitalizzazione che reinveste in R&D (Research and Development) permettendole di mantenere un tasso di crescita importante.

In un mercato sempre più orientato alla globalizzazione, un’azienda ambiziosa deve avere la lungimiranza di fare scelte importanti per il proprio futuro, come quella di dare nuovo respiro ad una crescita che negli ultimi 4 anni ha portato a raddoppiare il fatturato e di conseguenza anche il personale occupato.

L’area di Ferno, acquisita nel 2020 in piena pandemia, è in corso di riqualificazione totale ed auspichiamo diventi una realtà sempre più tecnologica e all’avanguardia sul territorio in grado di attrarre talenti perchè un’azienda non è fatta solo di strutture ed impianti ma è fatta soprattutto di persone e la realtà familiare di questa azienda rende ancor più vero questo concetto.

Oggi l’azienda conta oltre 50 addetti, molti giovani ed un alto tasso di ingegneri, in gran parte provenienti dal Politecnico di Milano, ma non solo.

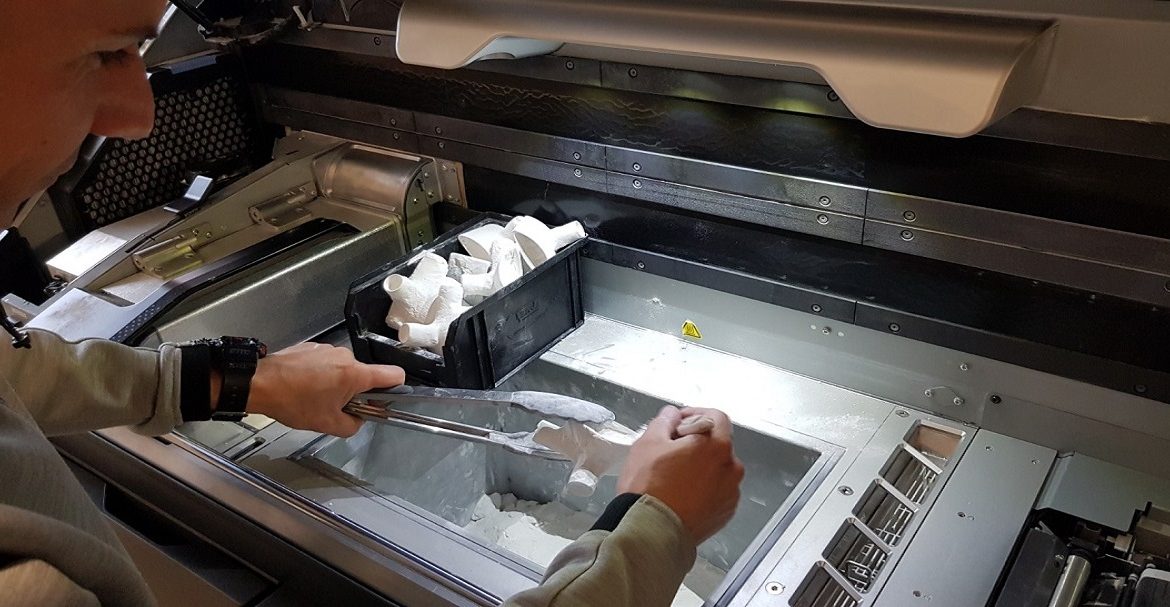

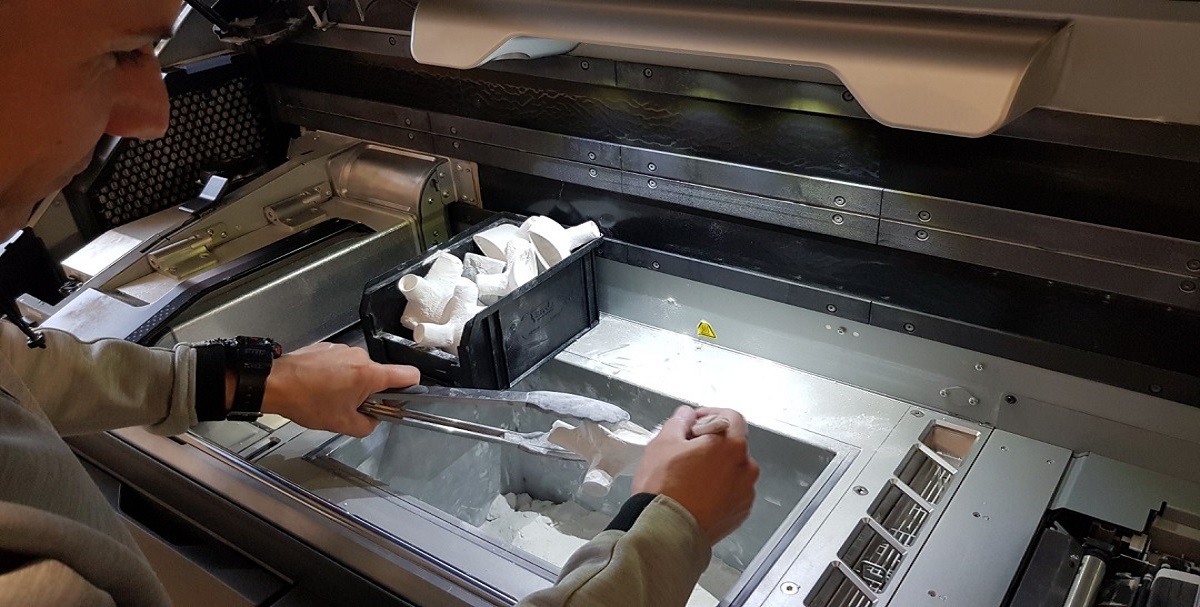

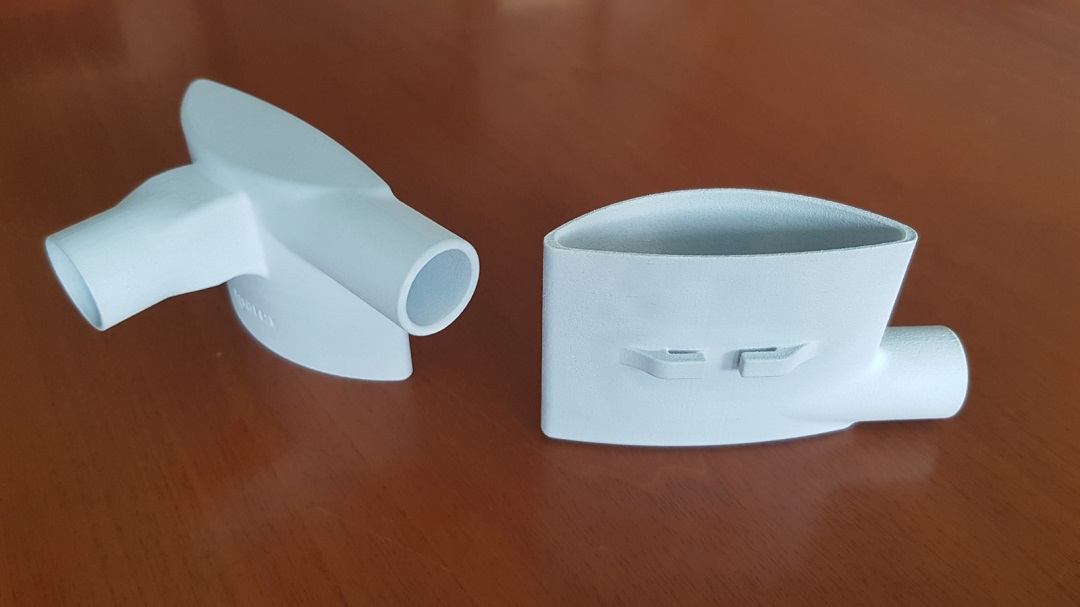

Il personale è impiegato nel reparto di ricerca e sviluppo, nell’area di additive manufacturing, nelle isole di produzione meccanica, nel reparto di assemblaggio elettronico automatico, nei reparti di assemblaggio finale, nella logistica e nel controllo della qualità.

«Nei prossimi mesi lavoreremo per realizzare al meglio e con serenità questo passaggio. – dice Stefano Pariani Accountable manager dell’azienda – L’attuale sede è stata voluta e costruita 23 anni fa da nostro padre, si tratta di un cambiamento importante, anche dal punto di vista emotivo, ma è senz’altro la migliore decisione per il nostro futuro».

La positiva esperienza sul territorio di Samarate, durata 3 generazioni sta per concludersi ma il legame storico con questo comune resterà comunque solido, la proprietà sta pensando che l’attuale sede possa essere destinata ad attività con un risvolto sociale.